What Are the Key Plastic Recycling Machines and How Do They Work

You see many kinds of Plastic Recycling Machines in recycling centers. Every Plastic Recycling Machine does a different job. Some machines melt plastic and change its shape. Other machines cut plastic into tiny pieces. Some machines clean plastic before recycling. The table below lists the main machines and what they do:

Type of Machine | Description |

|---|---|

Plastics Extruders | Melt plastic and change its shape |

Shredders and Granulators | Cut plastic into small pieces |

Plastic Washing Lines | Clean plastic before recycling |

These machines help recycling go faster and work better.

Key Takeaways

- Plastic recycling machines are different types. Each type has its own job, like shredding, washing, or melting plastics.

- Shredders cut big plastic items into small pieces. This makes them easier to move and get ready for recycling.

- Washing lines use water and soap to clean plastics. They make sure the plastics have no dirt or glue before recycling.

- Picking the right machines for your plastic type and amount helps save money. It also makes recycling work better.

- You need to take care of the machines often. Cleaning and changing old parts helps them work well and last longer.

Main Types of Plastic Recycling Machines

Shredders – Breaking Down Plastics

Shredders break big plastic items into smaller pieces. You can use them for bottles, barrels, trays, and pipes. These machines make plastic waste easier to handle. Shredders have strong blades that cut and squeeze plastic. This step gets plastics ready for other machines.

Function of Shredders | Types of Plastics Processed |

|---|---|

Make plastic waste smaller | Containers, pipes, car parts |

Help with handling and recycling | Bottles, oil bottles, gasoline bottles, plastic barrels, plastic trays, plastic baskets, plastic pipes |

Cut and squeeze materials | Bottles, oil bottles, gasoline bottles, plastic barrels, plastic trays, plastic baskets, plastic pipes |

Granulators – Creating Granules

Granulators take small pieces from shredders and make granules. You use granulators when you need tiny, even particles. These machines use fast knives to cut plastics. Granulators work best with clean, pre-cut plastic. They help you get the right size for melting or more processing.

Feature | Shredder | Granulator |

|---|---|---|

Particle Size & Uniformity | Makes rough, uneven chunks. | Makes small, even granules by screen size (3–18 mm). |

Cutting Mechanism | Uses slow, strong cutting. | Uses fast, sharp knives for clean particles. |

Speed, Torque & Power | Slow speed, strong power for tough materials. | Fast speed, medium power for fine pieces. |

Feeding & Operational Needs | Takes big, messy, or dirty plastic easily. | Works best with clean, cut plastic to avoid problems. |

Crushing Machines – Size Reduction

Crushing machines make plastic waste even smaller. They break plastics into flakes or granules. This makes recycling easier and saves space.

Mechanical recycling uses machines to recycle plastic waste. It includes steps like grinding, washing, drying, and making new granules. This lets plastics be reused many times without changing their basic parts.

Crushing machines have safety features like auto stop and guards. These keep you safe and help machines work well.

Washing Lines – Cleaning Plastics

Washing lines clean plastics before recycling. They use water, soap, and scrubbers to remove dirt and glue. Clean plastic is needed for good recycled products. Washing lines often reuse water to save resources. These machines get plastics ready for the next recycling steps.

Dryers – Moisture Removal

After washing, plastics must be dry. Dryers take water out of plastic flakes or granules. Wet plastics can cause problems when melting and shaping. Dryers use heat and air to lower water levels, sometimes below 3%. This helps make strong, good recycled plastics.

Dryer Type | Description |

|---|---|

Hopper Dryer | Used in molding and extrusion, dries granules with hot air. |

Energy Saving Hopper Dryer | Uses inverter control for cheaper hot air drying. |

Desiccant Dryer | Needed for special plastics, gives very dry air for exact jobs. |

Energy Saving Desiccant Dryer | Saves energy and gives dry air for special plastics. |

Extruders – Melting and Shaping

Extruders melt plastic and push it through a shaped hole. This makes new products. You use extruders to turn granules or flakes into strands or sheets. The temperature in extruders is usually 160°C to 300°C. This step is important for making new shapes and getting plastics ready for pelletizing.

- Plastic extrusion temperatures are usually 160°C to 300°C, depending on the plastic.

Pelletizers – Making Pellets

Pelletizers turn melted plastic into small pellets. These pellets are usually 3mm to 5mm. You use pellets to make new plastic things. Pelletizers make waste easy to handle and store. This step is important for finishing the recycling process.

Pellet Size Range |

|---|

3mm - 5mm |

Mixing & Compounding Systems – Blending Materials

Mixing and compounding systems mix plastics and additives. You use these machines to make recycled plastics better. Additives can be colorants, stabilizers, flame retardants, and more. Mixing systems help you make strong and useful plastics.

- Anti Counterfeiting

- Antimicrobials / Biostabilisers

- Antioxidants

- Antistatic Agents

- Biodegradable Plasticiser

- Black Masterbatch

- Blowing Agents

- External Lubricants

- Fillers/Extenders

- Flame Retardants

- Fragrances

- Heat Stabilisers

- Impact Modifiers

- Internal Lubricants

- Light Stabilisers

- Pigments

- Plasticisers

- Process Aids

- Reinforcements

Mixing and compounding systems help you make custom recycled plastics.

Balers – Compressing for Storage

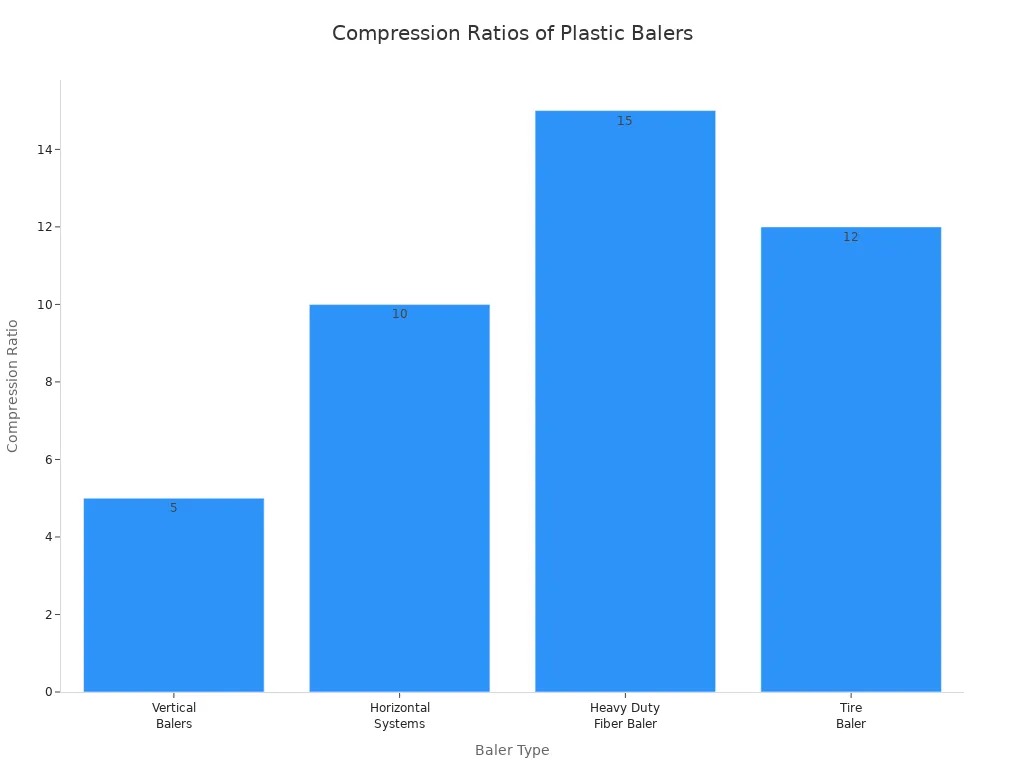

Balers squeeze plastic waste into tight bales. You use balers to save space and make storage easier. These machines can shrink plastic by up to 15 times. Balers help you spend less on waste and keep recycling working well.

- Vertical balers squeeze plastic 4 to 6 times smaller.

- Horizontal balers can squeeze up to 10 times smaller.

- Heavy Duty Fiber Balers squeeze up to 15 times smaller.

- Tire Balers squeeze up to 12 times smaller.

Balers help you handle lots of plastic waste easily.

Recycling Process Overview

Step-by-Step Workflow

Recycling plastic follows a simple path. Each step uses a special machine. These machines help turn waste into new things. Here is how it usually goes:

- Collection: You pick up used plastics from bins nearby.

- Sorting: You separate plastics by type, color, or thickness. Machines or people can do this job.

- Washing: You wash plastics to get rid of dirt, labels, and glue.

- Shredding: You use shredders to break plastics into smaller bits.

- Identification of Plastics: You test and sort plastics by density or other features.

- Compounding: You use machines to turn shredded plastics into pellets for making new things.

Each step gets the plastic ready for the next one. This helps you get the best results.

Machine Interaction in the Line

Plastic Recycling Machines work together like a team. Sorting machines separate plastics first. Washing lines clean the sorted plastics. Shredders and granulators break plastics into smaller pieces. Dryers take out water so plastics do not stick together. Extruders melt the clean, dry plastic and shape it. Pelletizers cut melted plastic into small pellets. Mixing and compounding systems add things to make plastics better. Balers squeeze leftover waste for easy storage.

- The order of machines is important. Good sorting means less contamination. Cleaner plastics make better recycled products.

- New AI sorting machines can spot plastic types very well. This helps you get cleaner and better recycled materials.

Efficiency and Sustainability

You can make recycling better by picking the right machines. Using machines in the best order helps a lot. Advanced recycling machines work faster and use less energy. Good sorting and washing steps give you cleaner plastics. This means less waste and better products. Modern machines help the environment by saving resources and lowering pollution. The quality of recycled plastic depends on the machines and steps you use.

Tip: Always match your machines to the type and amount of plastic you recycle. This saves money and helps the planet.

Selecting Plastic Recycling Machines

Factors to Consider

Think about your business size when picking machines. You should also think about what plastics you recycle. Your budget matters too. Big recycling centers need machines that work fast. These machines can handle lots of plastic at once. Small businesses want cheaper machines. They also want machines that are easy to fix. Machines that use less energy help save money. This is important for big recycling centers.

Factor | Small Operation | Large Operation |

|---|---|---|

Production Capacity | Lower | Higher |

Cost | Focus on savings | Invest in efficiency |

Maintenance | Simple upkeep | Advanced systems |

Energy Use | Moderate | Energy-saving crucial |

Matching Equipment to Needs

Pick machines that match the plastics you recycle. First, figure out what plastics you have. These can be PET, HDPE, PVC, LDPE, or PP. Each type needs a special process. A plastic pulverizer machine makes PVC, PE, and HDPE into powder. If you need plastic powder, use a plastic powder machine. This machine gives you better control. A PVC pulverizer machine grinds PVC fast. It does not get too hot. Always check if your machines fit your needs. Make sure they work well with your plastics.

- Write down the plastics you recycle.

- Choose machines made for those plastics.

- See if the machine can handle your daily work.

- Make sure the machine fits your space and budget.

Tips for Efficiency

You can make recycling better by using smart steps. Sort plastic waste before you start. Shred or granulate plastics into small bits. This helps with washing and drying. Use friction washers or hot wash systems to clean plastics. Use detergents that clean but do not hurt the plastic. Rinse plastics to get rid of soap and dirt. Dry plastics with mechanical dryers. Check moisture levels to keep quality high.

- Sort and size your materials first.

- Control heat in extruders for good melting.

- Keep screw design and screen packs clean.

- Use machines that sort and shred by themselves.

- Check, oil, and clean machines often.

- Change old parts quickly.

- Do energy checks to find ways to save power.

Tip: Pick machines that fit your needs. Take care of your machines. This helps you recycle more and save money.

You help plastic recycling work better. If you know what each machine does, you can pick the best ones. The right machines save energy and money. They also help your business run well. Many companies get their money back in a few years. If you use smart tools and follow guides, you help the earth. You also make recycled plastics better.

- Strong machines break less and cost less to fix.

- Machines that use less energy lower your bills and make more products.

- Good machines need fewer fixes and give better help.

Choose machines that fit your goals. This helps your business and the planet.

FAQ

What types of plastics can you recycle with these machines?

You can recycle PET, HDPE, PVC, LDPE, and PP. Each machine works best with certain plastics. Always check the machine's manual for the right material.

Plastic Type | Common Use |

|---|---|

PET | Bottles |

HDPE | Containers |

PVC | Pipes |

LDPE | Bags |

PP | Packaging |

How do you keep plastic recycling machines working well?

You should clean, oil, and inspect machines often. Replace worn parts quickly. This keeps machines safe and helps you avoid breakdowns.

Tip: Set a weekly schedule for maintenance. This helps you catch problems early.

Can you recycle dirty or mixed plastics?

You need to sort and wash plastics before recycling. Dirty or mixed plastics can damage machines and lower product quality. Use washing lines and sorting systems for best results.

- Sort plastics by type.

- Wash plastics to remove dirt and labels.

How do you choose the right machine for your business?

You should look at your daily plastic amount, types of plastics, and budget. Small businesses need simple machines. Large centers need high-capacity machines.

Note: Write down your needs before you buy. This helps you pick the best machine.